Solar panels produce their maximum power at a particular voltage, which may vary due to temperature, partial shading, sun angle, and other factors. This optimal voltage at which the most power is extracted from the panel is called the maximum power point. Choosing a solar charge controller with maximum power point tracking (MPPT) ensures that you’re getting this maximum power all the time. All Sunforge MPPT controllers, including Genasuns, maximize photovoltaic power generation by operating the panel at its optimal voltage and delivering the power efficiently to the battery—even when the battery is at a different voltage.

Before choosing the appropriate charge controller, it is important to determine if the panel’s voltage at maximum power (Vmp) needs to be decreased (bucked) or increased (boosted) in comparison to the nominal battery voltage being charged.

All solar charge controllers are power converters: by adjusting the current, they convert the fluctuating voltage produced by your solar panel to the voltage your battery requires as input. Buck converters step the voltage down from high to low while increasing the current. In contrast, boost converters step up your voltage from low to high while decreasing current.

Remember, the relationship between power (P), voltage (V), and current (I) is:

P = I • V

By simultaneously increasing the current when decreasing the voltage and vice versa, we’re ensuring that the same amount of power is transmitted in both situations. This means that whether you’re bucking or boosting, all the available power from your solar panels is delivered to your batteries and loads.

How does a buck controller work?

(and when should I use one?)

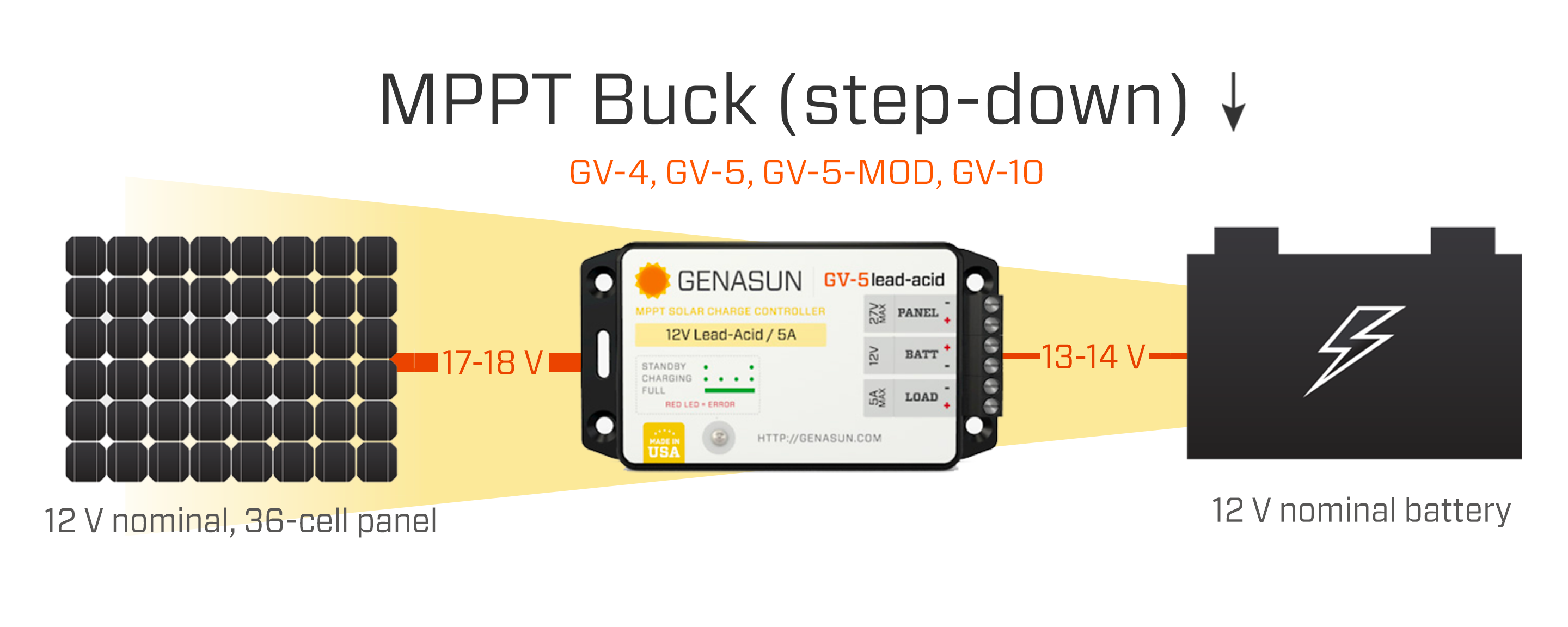

Use a buck controller when you want to charge a lower-voltage battery with a higher-voltage panel. For example, a 36-cell, “12 V nominal” solar panel has a Vmp around 17-18 V. This is higher than the charging voltage of a 12 V nominal battery (which is typically around 13-14 V). Therefore, if we want to charge a 12 V nominal battery (e.g., a car battery) with solar, we’ll need to use a buck controller.

The Genasun GV-4, GV-5, GV-5-MOD, and GV-10 are buck charge controllers, designed to step down the panel’s Vmp and deliver the max power possible when the battery is at a lower voltage (e.g., 12 V nominal).

| Model | Max. Output Current | Max. Recommended Panel Power |

|---|---|---|

| GV-4 | 4.0 A | 50 W |

| GV-5/GV-5-MOD | 5.0 A | 65 W* |

| GV-10 | 10.5A | 140 W |

Let’s do the math. A 36-cell solar panel producing its rated output of 100 W under Standard Test Conditions (STC) has a Vmp of about 17-18 V, which makes its output current at maximum power (Imp) approximately 5.5 A. This output from the panel becomes the input to the controller. GV-10, after bucking down the Vmp, will deliver about 8 A of output current at 12.5 V, which equals all of the original 100 W from the panel.

I • V= P

Panel output: 5.5 A • 18 V ≈ 100 W

Controller output : 8 A • 12.5 V = 100 W

The Genasun GV-4, GV-5, GV-5-MOD, and GV-10 will charge the battery any time the input voltage (panel Vmp) is greater than the battery voltage and the input power is sufficient to operate the controller. For optimal results, however, the input voltage should be approximately 0.4 V higher than the battery voltage on the GV-4 and GV-5/ GV-5-MOD, and about 1.0 V higher with the GV-10 (somewhat less with lighter loads). This would allow your Genasun controllers to produce their maximum output given the available input.

How does a boost controller work?

(and when should I use one?)

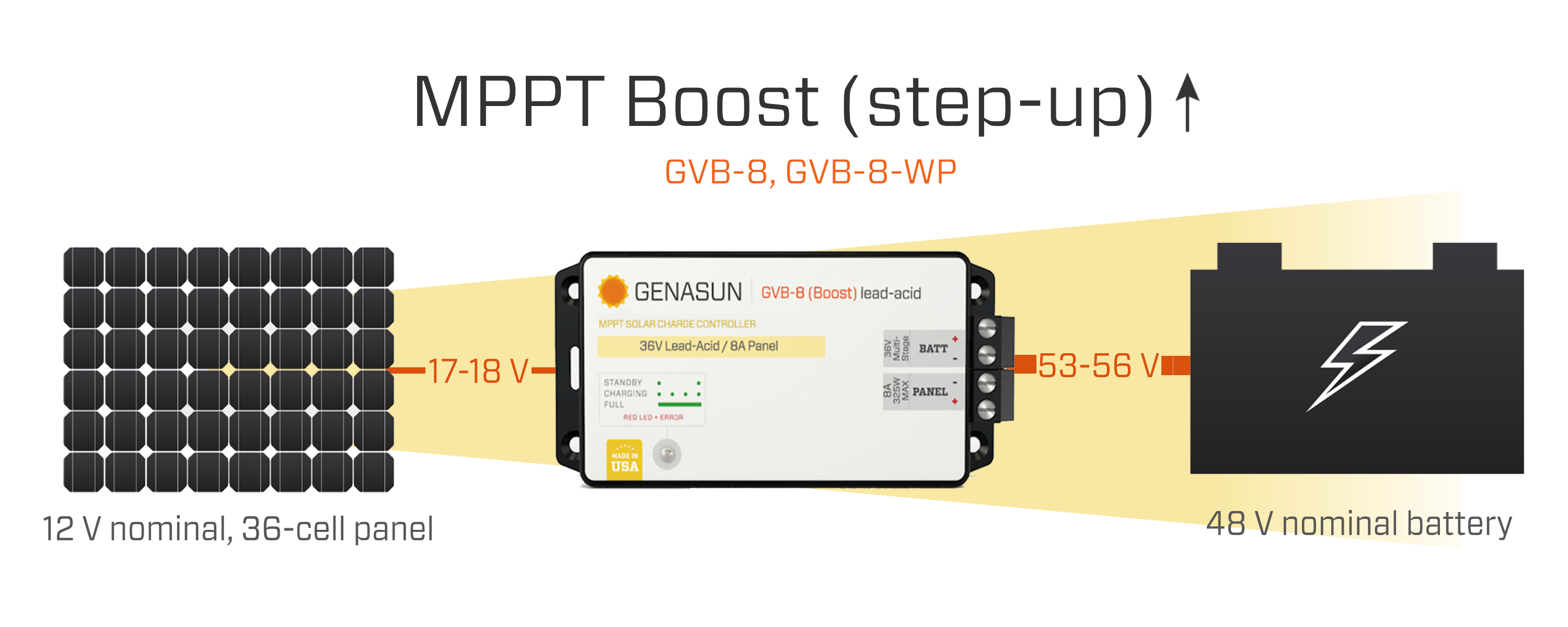

Use a boost controller, like the Genasun GVB-8 (Boost) or GVB-8-WP (Boost), when you want to charge a higher-voltage battery with a lower-voltage panel or when you want to boost the voltage output to keep charging the battery with a reduced panel Vmp due to a partial shade (typical conditions on sailboats) or due to suboptimal sun irradiations (typical conditions in mobile applications).

For example, if you had a GVB-8, the same 100 W, 36-cell (12 V nominal) panel previously mentioned could be used to charge up to a 48 V nominal battery. The GVB-8 would boost the 5.5 A, 18 V input from the panel to yield an approximate output of 2 A at 50 V (about the right voltage for a 48 V nominal battery).

I • V = P

Panel output: 5.5 A • 18 V ≈ 100 W

Controller output: 2 A • 50 V = 100 W

Here’s another example using a semi-flexible, 20-cell solar panel (9 V nominal with a Vmp around 13 V): the GVB-8 can boost the voltage from the 9 V nominal panel to charge a 12 V nominal (or higher) battery.

The GVB-8 and GVB-8-WP are designed to work with a maximum input current (Imp) of 9A. The maximum panel wattage is dependent upon the battery voltage being charged, as you can see in the following table.

| Panel # Cells | Panel Vmp | Nominal Battery Voltage | Max. Recommended Panel Power |

|---|---|---|---|

| 20/24 cells | 9-13 V | 12 V (or higher) | 105 W |

| 36/48 cells | 18-25 V | 24 V (or higher) | 210 W |

| 60/72 cells | 30-45 V | 36 V or 48 V | 325-350 W |

The minimum panel Vmp (aka, minimum input to the charge controller) is 5V for the GVB-8/GVB-8-WP series. In order to harvest power efficiently, the Vmp needs to be less than or equal to the battery voltage. If the Vmp is higher than the battery voltage, these are no longer ideal conditions for boosting, but the GVB-8/GVB-8-WP will still function by reducing the panel input voltage.

Lastly, it is worth mentioning the nearly non-existent power consumption of the Genasun controllers. We put a lot of care and meticulous engineering into their design, enabling Genasun controllers to have both the lowest operating consumption and lowest night consumption on the market. By comparison, competing controllers tend to draw ten times (or more!) current than our Genasun controllers. This is something we’re really proud of, and we hope you take advantage of it.

| Model | Night / Standby Consumption |

|---|---|

| GV-4 | 0.09 mA (90 uA) |

| GV-5 / GV-5-MOD | 0.125 mA (125 uA) |

| GV-10 | 0.9 mA (900 uA) |

| GVB-8 / GVB-8-WP | 5-7 mA |

As always, please drop us a line if you have any questions.